All of you know GMI for the manufacturing of advanced composite repair equipment and the development of innovative repair methodologies and solutions.

Some of you may have heard that GMI started more than 30 years ago as autoclaves and ovens manufacturer and a great number of such equipment is now operational worldwide.

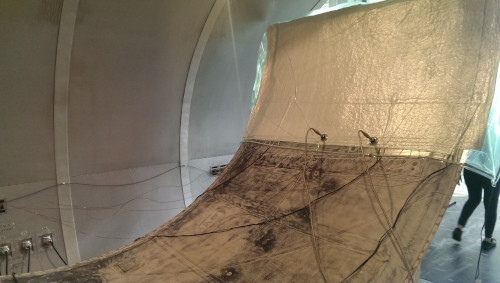

However, only few of you know that GMI now upgrades existing autoclaves to become “Repair Enhanced Autoclaves – REA”, using flexible blankets as the main source of heating!

Even though this may sound “controversial”, this is the state-of-the-art heating solution for addressing repair requirements of complex aeronautical parts, such as the A380 engine reverses, the B777/B787 engine nacelles etc. Indeed, globally heating the parts in “conventional” autoclaves would immediately distort them while causing severe and unrecoverable damage, due to variation of thermal expansion coefficients of involved materials.

So, even though an autoclave is still used to provide required pressure and slightly elevated ambient temperature (i.e. 50-80oC), heating at 120-180oC is ensured using specially designed adapted heating blankets, at the repair area ONLY!

Airlines and MROs could thus easily upgrade their existing infrastructure to “Repair Enhanced Autoclaves – REA”, as GMI could support them through:

Installation of power supply plugs, connectors, extension cables.

Thermal simulation and analysis of the repair area to ensure Temperature homogeneity.

Design and manufacturing of adapted heating blankets, tailored to the specific repair requirements.

The fact that GMI has implemented such operations to 3 major European MROs during 2018 further confirms the composite repair market advantage for entities adopting such solution, as a direct extension of their repair capabilities is achieved!