AFI KLM E&M is a renowned aerostructures expert, whose customers benefit from its 40 years' expertise in inspection, repairs, spares pooling and an extensive array of capabilities ranging from pure metal work to metal bonded honeycomb sandwich solutions, right up to advanced composite repairs. Recently, it has developed many new repairs and solutions for composite aerostructures through its “The MRO Lab” innovation program.

For its part, in the last 15 years GMI has participated in more than 25 EU funded R&D projects in the field of bonded composite repairs. The knowledge accumulated, in cooperation with major European Universities and aircraft manufacturers, enables GMI to develop innovative solutions to face contemporary repair challenges of end-users in the aviation industry.

The two companies recently combined their strengths and expertise to design an exclusive “adapted” thermal solution. Thegoal was to develop the appropriate range of heating elements for Out-Of-Autoclave (OOA) curing of the 777 GE90 engine nacelle.

Air France, being a major operator of this type of aircraft, was interested in a methodology for ~2m² internal skin replacement and subsequent curing at 177±5°C, in order to fully comply with the manufacturer’s specifications, while greatly reducing repair costs and TAT.

Overview of the GE90 area to be repaired, showing variations in construction materials and methodology (sandwich – monolithic)

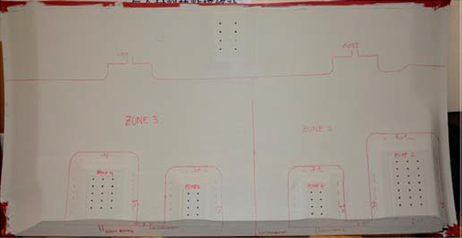

The 8-element / 5-zone adapted heating blanket, designed to cover the upper surface of the right /left cowling

The joint AFI KLM E&M-GMI team studied the thermal process and produced a heating mat fully adapted to meet manufacturer requirements to approve the repair. The mat is designed according to the geometrical profile and also to the thermal signature of the GE90 Nacelle. The heating mat has eight heating areas with the possibility of independently controlling the temperature in only six areas (see figure).

The heating blanket’s zonal architecture, including parallel connections, overlaid on the actual GE90 cowling (upper).

The developed heating system installed in vacuum bag during validation heating trials (left).

The solution has been approved by the joint AFI KLM E&M-GMI team, fully achieving the required temperature homogeneity across the entire repair area! The solution is now available to all 777GE90 users who want to significantly reduce their maintenance costs and TAT by OOA repair of their nacelles!