Quality assurance for adhesive bonding of aircraft composite structures by advanced NDT (ComBoNDT)

Funding scheme: H2020/ MG.1.1+2014.-RIA 636494-2

Participants: Fraunhofer IFAM, Airbus, CNRS, Univ. Patras, EASN, Aernnova

In its continuous pursue of excellence and innovation, GMI Aero has been selected by the European Commission to participate in almost 30 EU funded R&D projects in the last 10 years, always focusing on various aspects of bonded composite repairs. Thanks to those projects and to the integration of their results in our equipment, GMI can now propose state-of-the-art equipment and methodologies, facing contemporary repair challenges that arose with the venue of all-composite aircraft (A350, B787 etc.).

One of those recently finished Horizon 2020 projects was “Quality assurance concepts for adhesive bonding of aircraft composite structures by extended NDT – ComBoNDT”

Coordinated by Fraunhofer IFAM and empowered by a number of distinguished Universities, SMEs and End-users, ComBoNDT aimed at the development of more secure, time- and cost-saving extended non-destructive inspection tools (ENDT) for carbon fiber reinforced plastics (CFRP), adhered surfaces, and bonded CFRP joints.

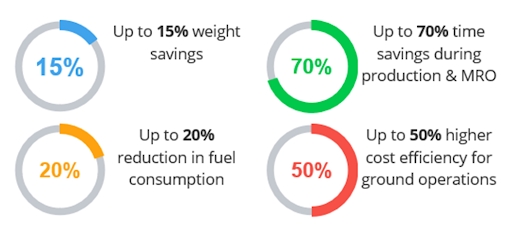

The successful developments within ComBoNDT therefore enabled:

The integration of such ENDT technologies into future adhesive bonding process chains, quality assurance concepts and material testing for maintenance processes will pave the way for safe and reliable integration of lightweight composite structures into the aircraft design. It allows the bonding of complex, lightweight structures and the replacement of rivets in order to overcome the use of CFRP as “black metal”.

The ComBoNDT main achievements were presented during a specially prepared “Demonstration Day” in Fraunhofer IFAM and can be viewed in the corresponding video.

The successful developments within ComBoNDT are expected to enable the optimal use of composite materials and to in turn allow:

Main GMI Aero participation into this project concerned the development of the magnetostrictive sensing methodology (see video available through GMI Aero Youtube channel

One of the main advantages of this methodology is the absence of connection or even contact of the sensing elements (magnetostrictive wires) to the measuring device. Using a single magnetic transducer, strain measurements are retrieved at any point of the concerned structure in a contact-free manner, thus facilitating inspection, especially in cases of monitoring of large areas. The proposed method could serve for fast – low cost components’ inspection at regular maintenance intervals, as well as for the improvement of aircraft certification procedures, providing part’s “strain signature” in a continuous manner (mapping), instead of spot measurements achieved today using strain gauges or OFBG sensors. Retrieved strain signature is subsequently compared against either previous readings or theoretical models, in order to trace potential differences and / or anomalies, indicating damage.

Considering the rapidly growing volume of composite materials on modern aircraft and the increasing need for repairs of the older ones, it is expected that airlines and MROs using innovative GMI solutions as developed within the frame of several European R&D projects will be provided with a very important advantage compared to competition, in terms of range of available solutions, cost efficiency and performance.